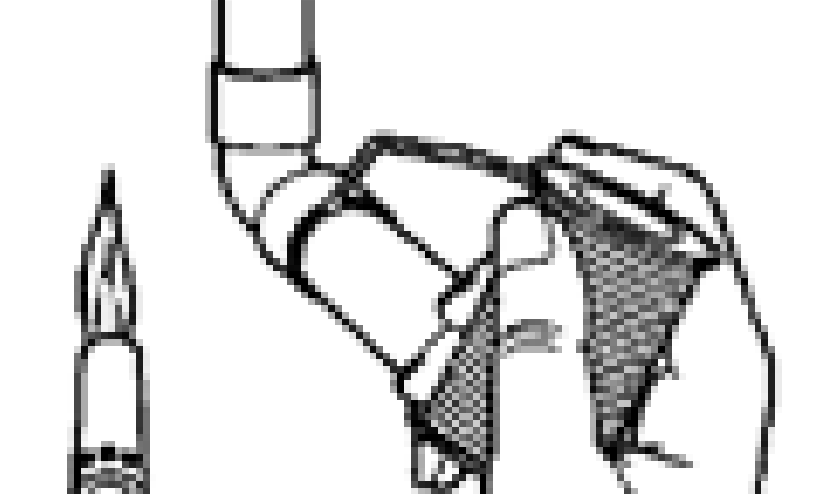

CAUTION: Do not overheat the joint or direct the flame into the face of the fitting cup. Overheating could burn the flux, which will destroy its effectiveness and the solder will not enter the joint properly.

1. Cut tube square with the cutter or fine hack saw (32 tooth

blade is recommended). Remove Burr.

2. Clean outside end of copper tube thoroughly with sand cloth or sandpaper equal depth of fitting. Leave no dark spots.

3. Clean inside of fitting carefully to tube stop with wire brush.

Note: Sand cloth or sandpaper may also be used.

4. Using a brush, apply light uniform coat of soldering flux to the outside of the tube and inside of the fitting.

5. Slip tube into fitting to tube stop. Turn tube back and forth once or twice to distribute flux evenly.

6. Apply heat uniformly around the fitting with torch. When solder melts upon contact with heated fitting, the proper soldering temperature has been reached. Remove flame and feed solder slightly off center at the bottom of the joint. Proceed across the bottom of the fitting and up to the top center position. Return to the starting point, and then proceed up the incomplete side to the top, again, overlapping the solder metal. Wipe off surplus solder with a piece of cloth.